- changes in materiel dielectric strength, loss of insulation resistance, variations in magnetic and electrostatic field strength;

- materiel electronic circuit card malfunction, electronic circuit card damage, and electronic connector failure. (On occasion, circuit card contaminants having the potential to cause short circuits may be dislodged under materiel response to gunfire environment);

- permanent mechanical deformation of the materiel as a result of overstress of materiel structural and non-structural members;

- collapse of mechanical elements of the materiel as a result of the ultimate strength of the element being exceeded.

- accelerated fatiguing of materials (low cycle fatigue);

- potential piezoelectric activity of materials; and

- materiel failure as a result of cracks and fracture in crystals, ceramics, epoxies, or glass envelopes.

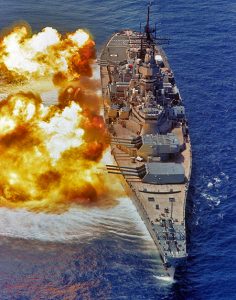

This is a very complicated Method in that the effects of air pressure pulse is combined with shock through the structure with distance from the gun having a significant impact on which input has more effect. In addition, predicting material response may be impossible. The Method relies heavily on Method 525 (Time Waveform Replication). There are three procedures: Procedure I – Measured in-service gunfire shock environment for materiel is replicated under laboratory exciter waveform control (Method 525 TWR) to achieve a near exact reproduction of the measured in-service gunfire shock environment. Procedure II – This procedure is based upon either (1) direct stochastic generation of time traces appropriate for Method 525 that are “equivalent” in severity to in-service measured time trace information, or (2) a procedure that may be justified for properly distributing uncertainty, and for conservative testing (but in accordance with the principles of random process theory). Procedure III – This procedure is ad hoc, lacking necessary field measured time trace information, and a last resort to providing guidelines for design of materiel to resist gunfire shock environment. Only time trace forms for design are given, and it is not suggested that testing be performed to these forms for materiel qualification purposes. Gunfire Shock testing is performed on a shake table with the ability to follow test waveform inputs.