Case Study – March 2013

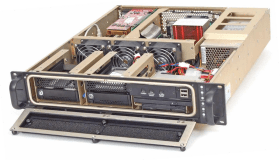

Before utilizing our rugged 2U computer in their submarine application, our client needed to verify that the enclosure could pass MIL-S-910D high impact shock tests required by the U.S. Navy. In order to enable our customer to authenticate the ruggedness of the equipment, we provided an enclosure to be used for the various required tests.

High Impact Shock Qualification Test (MIL-S-910D)

As part of a larger rack mount system, our subsystem enclosure was subjected to the High Impact Shock Qualification Test, designed to establish Grade B, Class I, Type A shock qualification as specified byNAVSEA’s General Overhaul Specifications for Deep Diving SSBN/SSN Submarines document, in accordance with Project Peculiar Document (PPD) Requirements for Shock Tests, High Impact Shipboard Machinery, Equipment and Subsystems, as modified by Specifications for Building Submarines, SEAWOLF Class.

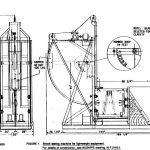

The testing performed is meant to simulate an event by mounting a weighted chassis into a rack which is attached to an anvil plate simulating a bulkhead. This is then struck with a 400 pound hammer from a height of 1, 3 and 5 feet from each axis, top, back and side. See the drawing from MIL-S-901D showing the shock apparatus.

The testing performed is meant to simulate an event by mounting a weighted chassis into a rack which is attached to an anvil plate simulating a bulkhead. This is then struck with a 400 pound hammer from a height of 1, 3 and 5 feet from each axis, top, back and side. See the drawing from MIL-S-901D showing the shock apparatus.

Results of the Shock Tests

The CP Technologies R2U enclosure passed the test without exception and with no required rework or modification. Often this high level of abuse will reveal a chassis deficiency that requires an engineering correction. This was not the case for the CP Technologies’ enclosure which passed on the first test which validates CP Technologies design practices and mechanical engineering prowess.

CP Technologies has over a decade of experience solving customers design requirements. For more information, see some of our other case studies.